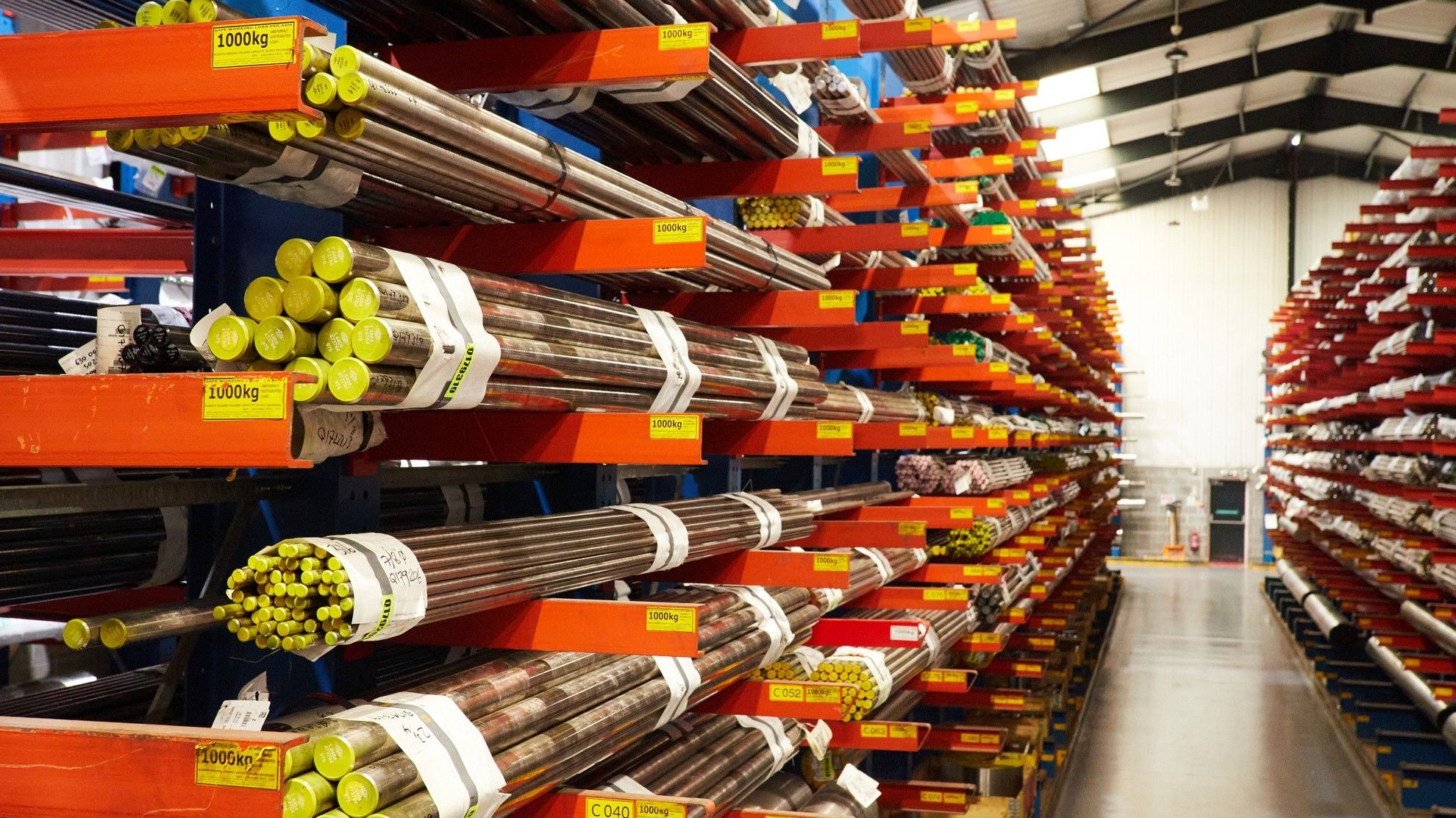

Leaders in Stainless Long Products

Dedicated To Meeting Your Steel Needs Cogne U.K. Limited was established in February 1997 by Cogne Acciai Speciali, a leading European special steels manufacturer.

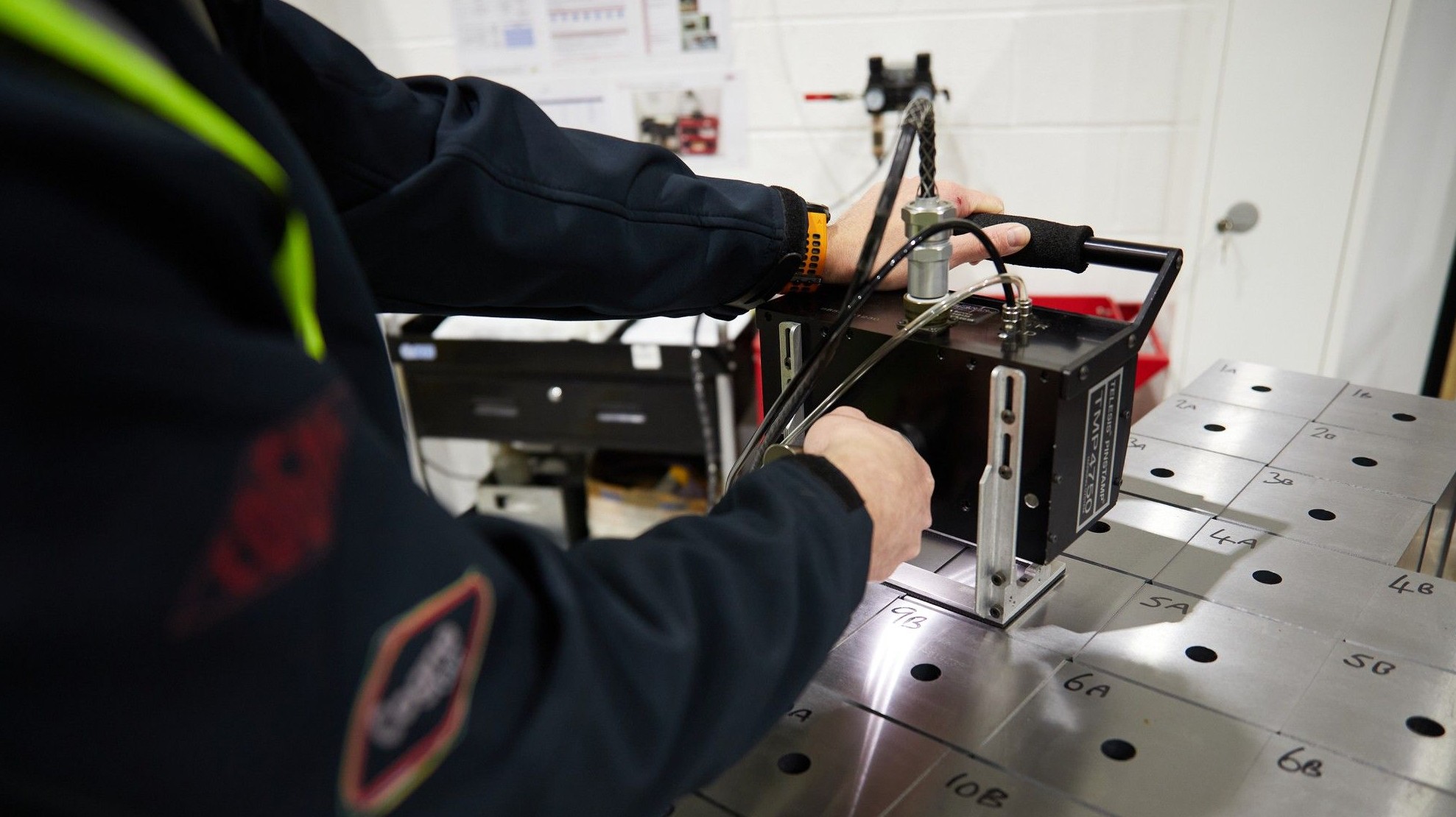

Working Efficiently

At Cogne U.K. Limited, we prioritise understanding and fulfilling customer needs through efficient and effective processes.

learn more